The conception and design of ventilation systems for operating conditions with variable pollutant loads (DCV) is a modern and effective method, properly described and regulated in national and international standards (ASHRAE 62.1 – 2019 item 6.2.6.1). Its use is based on real-time monitoring of the concentration of pollutants and the controlled intake of outdoor air (renovation). The use of purification systems associated with DCV minimizes the need for air renewal, contributing significantly to energy savings while ensuring high levels of indoor air quality (IAQ).

To mitigate those issues, the Indoor Air Purification process must associate the best filtering and decontamination techniques with recirculation through a planned air flow and controlled intake of filtered outdoor air when necessary, through Air Purification Systems that are easy to install and cost effective.

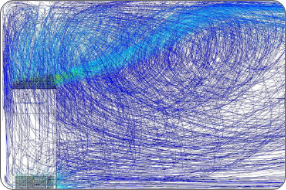

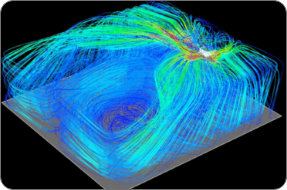

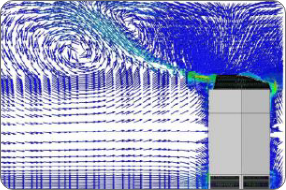

Planned Air Flow One of the main characteristics of the Purefeel® Products and Solutions, especially the UPR and UPO units, is the use of a known airflow pattern defined in computational study (CFD – Computing Fluid Dynamics) in the sizing of applications. This criterion provided for in the Applicable Standards (ASHRAE 6.2.1.2.1 and 6.2.1.2.2) allows the use of a much smaller volume of external ventilation air with equivalent or even better results in terms of Indoor Air purification. It also allows for significant savings in air conditioning energy. The unique design of the Purefeel Air Diffusers allows collimating the purified air outlet at 180◦, 135◦ and 90◦ angles, further optimizing air distribution in the areas of interest.

Current lines indicating speed side view

Current lines indicating speed top view

Speed field produced by the equipment in the confined environment

Purefeel® air purifiers units are equipped with an automatic outdoor air intake damper for controlled indoor air refresh when ventilation conditions so require. The volume of outside air intake is automatically controlled by the INTELIAR™ system, keeping the temperature and humidity within predefined limits.

An automatic damper connected to a piping and external air intake, commanded by the INTELIAR™ system, promotes the controlled renewal of the internal air when necessary.

INTELIAR™ is a unique Software that takes Indoor Air Quality (IAQ) to another level, overcoming the difficulties that have prevented the technique to be used more frequently in ventilation and air conditioning projects in commercial, public, industrial, education institutions and health care buildings.

The technology developed by Purefeel applies a series of sensors with a unique automation software that provides all necessary conditions to ensure that the Air Purifier operates only under the specified conditions.

Sophisticated routines of Purefeel own indoor air quality analysis algorithm (IAQ-i) allow air flow optimization and minimizes outdoor air intake (DCV), with significant energy savings while facilitating operation, ensuring integrity and operational compliance.

The high degree of filtration and the controlled intake of outdoor air managed within a defined limits range of temperature and humidity variation, keep the concentration levels of pollutant under control, whether particulate (PM) or gaseous (CO2, TVOC, CH2O and three more customizable substance possibilities).

The relationship between the reduction of infections by viruses and bacteria with the reduction of suspended airborne particulates, especially PM2.5, is widely proven in numerous scientific studies (Bacterial characterization in ambient submicron particles during severe haze episodes at Ji’nan, China; Caihong Xu et.al, 2017). This ensures indirect monitoring of the microbiological load levels of Indoor Air.

Software Management functions include: |

Real-time monitoring of the concentrations of particulate matter (PM10 and PM2.5), CO,, CH2O and TVOCin the air with optional alarm function and automatic assumption of the maximum purification flow available if necessary. In addition to these substances, the technology allows the addition of up to threemore contaminants from a list of pollutants that most often affect indoor air quality. Particle Monitoring allows indirect control of the microbiological load of the Air; |

Intelligent operation cycles based on pollutants monitoring and local or cloud scheduled timer allowing high energy savings; |

Controlling of the filter elements (except activated carbon) and indication of the expected life span and expected date of replacement based on the actual operating conditions, with optional alarm and forced shutdown; |

Following-up life span of the Activated Carbon Filter and forecast of the exchange date with an alarm; |

Controlling the operation of the Ultraviolet unit with indication of lamp failure (burnt out). UVC (ultraviolet) |

Maintenance of constant preset air flow throughout the operation regardless the degree of saturation of the filter elements; |

Validation routine of the specified replacement filter cartridge; |

Automatic management of the inlet outdoor air in the inlet chamber based on monitoring of the indoor air quality (IAQ-i) and the allowable outdoor air volumes according to the permissible variation of temperature and humidity (DCV); |

Supervision of the operation integrity with forced shutdown in case of inconsistent assembly, maintenance and/or operating failure; |

Wi-fi Connectivity by APP with an operation mirroring |

Process and Control of access levels in accordance with FDA regulations (CFR 21 - Part 11). |

Particulates, Gases and Microbiological Load Reduction

The most advanced filtration technology is used in Purefeel´s Products and Solutions. The document “ASHRAE´s Position on Filtration and Air Cleaning“, in its Abstract, states that”… there is only significant evidence of health benefits for porous media particle filtration systems”. This statement, largely based on scientific evidence, places the mechanical filtering in a privileged position when it comes to indoor air purification.

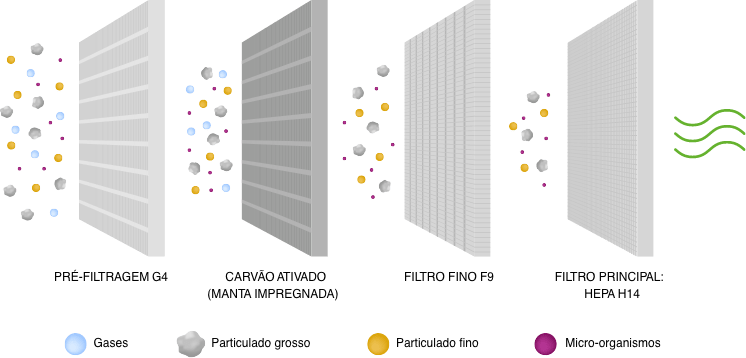

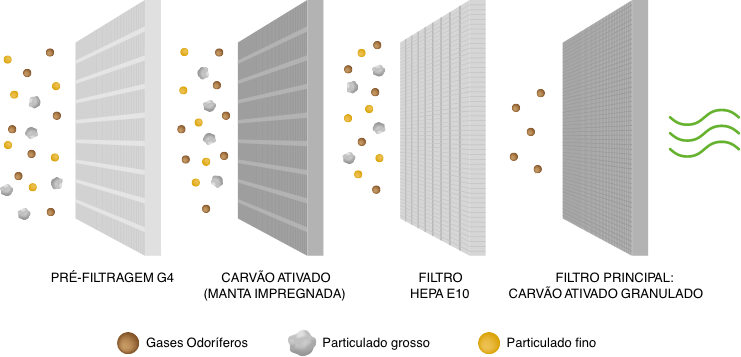

Supported by scientific evidence, Purefeel’s Products and Solutions include at least three filtration stages:

The relationship between the reduction of infections through viruses and bacteria with the reduction of airborne particulates, especially PM2.5, is widely proven in numerous scientific studies (Bacterial characterization in ambient submicron particles during severe haze episodes at Ji’nan, China; Caihong Xu et.al, 2017). Additionally, it is also possible to choose to use activated carbon filter elements for gas absorption, especially in odor control applications.

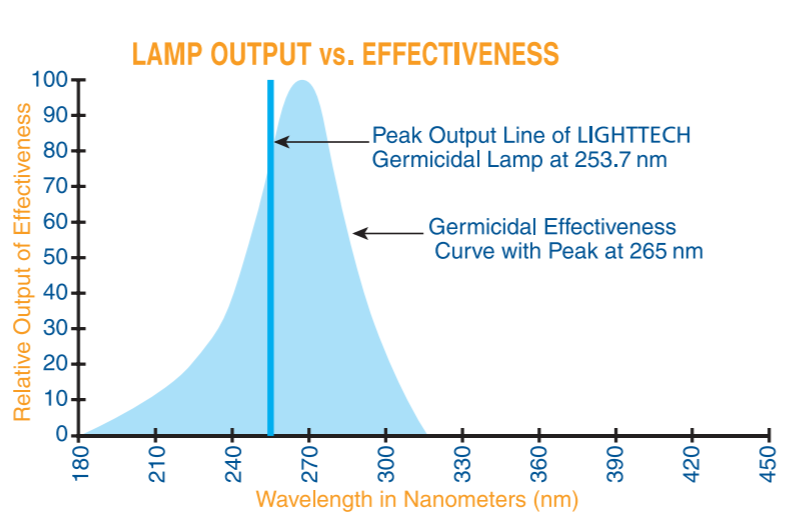

To optimize the improvement of indoor air quality, a proportional intake device for filtered outdoor air can also be used. A UVC source is positioned inside the clean air flow, sheltered from the access of people, avoiding, at the same time, loss of efficiency caused by dust deposited on the lamp bulbs, ozone emission in the environment and direct visual contact. The impossible task of sterilizing air in such a short exposure time within the air flow, as has been reported in other applications and models, was replaced by an innovative application that reduces the possibility of microorganisms contamination of the filter element and internal components of the equipment.

Applications & Services

The criteria for dimentioning and selecting Purefeel´s Products and Solutions is based on solid engineering principles and practices.

Analysis of the filtering needs, the intake filtered outdoor air volume and the specification of the type of monitoring and control, takes the needs of each specific environment into account, considering, among others, the following aspects:

Purefeel´s solutions are dimensioned one by one for the actual operating conditions based mainly on the above criteria. Thus, unique INTELIARTM technology offers maximum performance in operational integrity functions, preventing the purification systems from operating out of the original specified conditions.

These strict engineering criteria are also the basis of the advisory and consultancy services provided by Purefeel: ![]() .

.

Compliance with local regulations and international legislation is a key differentiator of Purefeel® products and solutions compared to most of products available on the market.

Its construction fully meets the requirements of the standards:

The proper use of Purefeel® products ensures compliance with the legal aspects that supports the obligation of systematic control of Indoor Air Quality in Brazil:

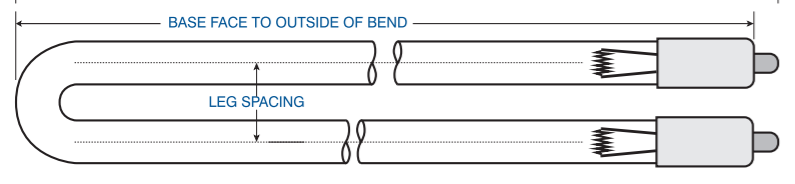

A UVC chamber – Ultraviolet Light in the wavelength range C with a power of 2 x 55W – positioned within the clean air flow, sheltered from people’s access, at the same time avoids loss of efficiency caused by dust deposited in the bulbs. lamps, emission of ozone into the environment and risk to personal safety due to direct eye contact. The impossible task of sterilizing the air in such a short exposure time within the flow, as has been widely disclosed in other applications and models, was replaced by an innovative application that reduces the contamination of the main filter element and the Unit’s internal components by microorganisms , including after maintenance operations.

Sign up for our newsletter and stay on top of news